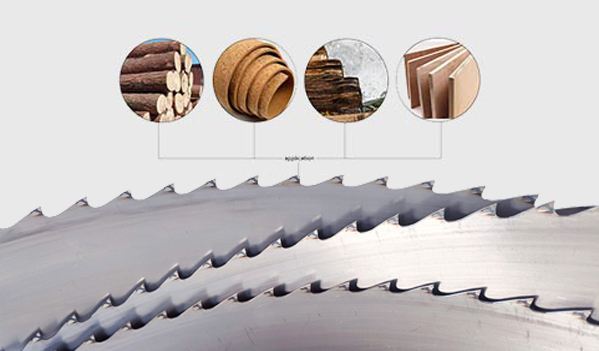

| Material | Stellite Tipped Bandsaw Blade |

| Application | Woodworking |

| Thickness | 1-1.5mm |

| Thickness | 1-1.5mm |

| Width | 80-160mm |

| Note: Customized service available | |

Production Process:

Teeth Punching, use a punching machine or Waterjet to process the raw material according to the customers' required tooth spacing.

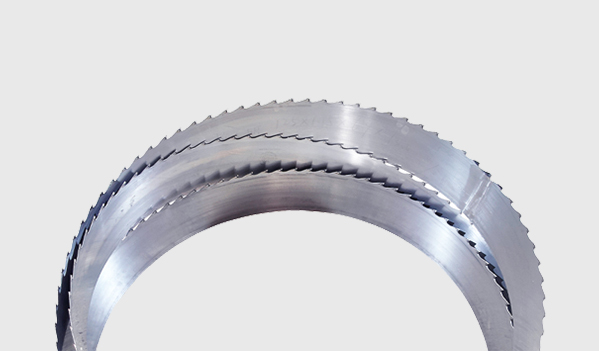

Cutting, measure and chop the saw blades to the finished size.

Welding, trim the end of the saw blade to be welded, and then put it into the two-electrode pressure plate of the machine for butt welding.

Annealing, set the blade to the annealing temperature suitable for the steel strip.

Grinding Weld Seam, the weld seam needs to be ground, leveled, and straightened before the teeth welding.

Teeth Welding, use resistance welding technology to weld the stellite saw teeth to the band saw blade.

Teeth Grinding, grind the front, back, and sides of each tooth to get them sharp with almost no burrs.

Roller Processing, use a roller press to evenly distribute the stress in the steel band.

Marking, mark the blades.

Packaging, oiled and packed

Product Advantages:

Sharper blades

Cleaner cutting

Uniform cutting geometry

Longer blade lifetime

Minimum downtime

Minimal yield loss

Company Advantages:

SYTOP provide one-stop service, we have stellite bandsaw blades, circular saw blades, frame saw blades, stellite saw teeth, stellite welding rods, and we can also help you to purchase various machinery for woodworking.

SYTOP has a professional technical team to customize production completely according to customer requirements.

Shenyang Top New Material Co., Ltd. is a leading manufacturer of stellite alloy in the past 20 years, now we will supply high-quality woodworking tools and equipment based in China. SYTOP is committed to innovation and excellence, and our products reflect our dedication to providing our customers with the best tools in the industry.